A blender is a machine with a blade-mounted shaft rotating in a cylinder or groove, mixing various ingredients to form a mixture or suitable consistency. Mixer is divided into many kinds, there are forced mixer, single horizontal shaft mixer, double horizontal shaft mixer and so on. Stone mixer using the rapidly rotating screw to the raw material up to the top from the bottom of the barrel by center, again with umbrella fly scattered, back to the bottom, so raw materials within the barrel roll up and down, in a short period of time can be finished a large amount of raw material evenly mixed. With automatic timing operation, overload protection, charging limit alarm, etc; And has the occupation small, the capacity is big, consumes the power low, the province artificial, the control is convenient, the mixture is quick and uniform and so on the merit.

Equipment workflow:

1. Start the inverter of the main stirring tank, and then transfer the stone powder material to the main stirring tank through the transmission belt. The inverter runs at different speeds according to the instructions issued by the PLC control system. On the premise that the converter does not stop, add the resin pigment to the main stirring tank and stop after running for about 30 minutes.

2. While the main stirring tank is working, the secondary stirring tank is also doing the same work, only with a small amount of stirring material. After the main stirring tank is shut down, pour the material stirred by the secondary stirring tank into the main stirring tank. During the feeding process, the main motor inverter runs with an inching motion of 10Hz. After the pouring, the main tank is covered with a lid and pumped into a vacuum.

3. Feed the stirred stone into the hydraulic forming equipment, and then harden it naturally.

4. Send the hardened product into the marble row saw cutting equipment and cut into different thicknesses according to different designs.

5, will cut the material polished edge, so as to get the finished tile.

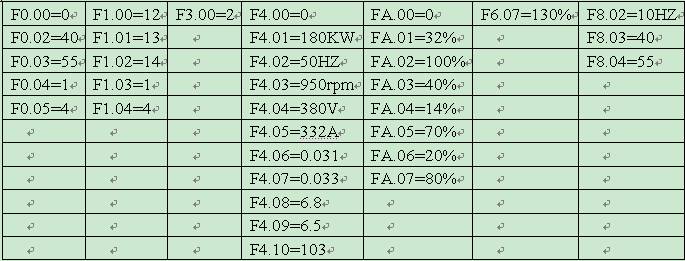

Converter parameters:

Inverter operation state:

In a charging (about 6.8 tons), after the completion of basic control inverter working current is controlled in 200 a, in the second feeding process moving, a frequency converter speed up the process of peak current in 510 a, about 120% of the rated current converter, secondary loading is completed (about 10 tons), 7 hz, accelerate the process of current control in 510 a, accelerate, after the completion of working current in the range of 330 ~ 350 a.

Advantages of AMB300 inverter:

The agitator is widely used in the industrial environment. Applied in the stone mixing equipment is very much also, frequency converter technology application on the device is quite mature, however, to make mixing equipment downtime in the operation process, and then start again,, it is not common inverter can finish the work, because stirring AMB300 inverter, with excellent internal algorithm, at the same time cooperate with master TI high-speed chip, can quickly capture the running process of the current changes, and quickly calculate the suitable for the control of the load curve, in guarantee the equipment running at the same time, also can be a very good control suitable working current, is good enough to meet the process requirements.

The use of AMB300 inverter can be very good completion of the ceramic tile stone stirring equipment technology requirements.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|