A conveyor is a material handling machine that continuously transports materials on a certain line, also known as a continuous conveyor. Conveyor can carry out horizontal, inclined conveyor, can also form a space transport line, transport line is generally fixed. As a state-owned coal production enterprise, yunnan xiaolongtan mining bureau is one of the key mining areas of yungui coal base, a large-scale coal base approved by the state. It is an important energy production base in yunnan province, mainly producing lignite. In addition to the coal industry, there are also machine repair, construction, processing and service industries. At present, the five-phase expansion project is a key construction project of "double hundred" in yunnan province, which will be fully started in March 2008. After completion, the coal output will reach 14.9 million tons per year.

Project overview and design scheme

The main motor power of 502 belt conveyor is 2x800kW. In order to ensure safe production and reduce the impact on the equipment, the mining bureau, design, machine repair and other parties studied and decided to use high-voltage inverter drive. And in order to deal with the mechanical part of the larger error, the use of the inverter can be convenient to adjust the speed of the characteristics, the use of a towed one, two synchronous way.

Matching motor parameters

Operating principle and characteristics of system tape machine

The rubber belt machine drives the wheel drum to move the belt by friction. The belt drives the object to move on the supporting roller by tension deformation and friction. Rubber belt is an elastic energy storage material, which stores a large amount of potential energy when the belt machine stops and runs, which determines that the belt machine should be started by soft start. Most coal mines in China use hydraulic coupler to realize the soft start of the belt machine. When using hydraulic coupler soft belt machine, due to the narrow range of speed regulation, low speed start time is short, loading force is large, at the same time before and after driving the same belt is difficult to really solve the distribution and synchronization problem of load power and belt elastic potential energy power, easy to cause belt fracture and aging, requires the belt strength is high. In addition, long working hours of hydraulic couplers will lead to high internal oil temperature, wear of metal components, leakage and reduced efficiency, which will not only increase the maintenance difficulty and cost, but also pollute the environment.

Plan implementation

The two-machine communication processing system coordinates and controls the main and slave inverter systems, and communicates and transmits information to each other. The DCS system sends the operating frequency to the communication system, and the communication system transmits the given speed to the host machine, which then transmits the communication from the host machine to the slave machine. When host light failure from the opportunity to follow the opportunity to real time corresponding treatment measures are taken, also when malfunction from machine there is light, the host will also follow the host response processing measures, real-time detection processing system by means of double motor power at the same time, the real-time automatic adjustment for the Lord, from the motor synchronous operation, achieve the synchronous operation of the host and from the machine speed.

Inverter selection and main circuit description:

The inverter model is: amb-hvi-850-100-06, rated power is 850KW, rated voltage is 6KV, rated current is 100A; The quantity is 2 sets.

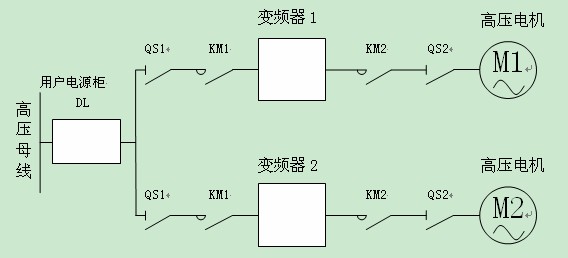

The main circuit of the converter is as follows:

1. Each inverter contains a full set of QS1, QS2, KM1 and KM2

2. QS is a single-pole isolating switch, KM is a vacuum contactor.

3. When KM is in the closed state, QS has mechanical latching and cannot be operated.

4. KM is controlled by DCS system for closing, and the closing state is maintained by electricity, and the coil has the ability of long-term charging.

The main performance is:

1. Soft start and soft stop at startup are realized to reduce the impact on the power grid.

2. The frequency of frequency converter is continuously adjusted to make the speed adjustment more convenient, reliable and stable.

3. After using the inverter, the original shifter contactor and speed-regulating resistance were eliminated, which saved the maintenance cost and reduced the downtime and maintenance time, thus increasing the output. At the same time, the harsh operating environment is improved, so that workers can avoid working under the high temperature condition when the speed regulating resistance becomes hot in summer.

4. It is very effective at low speed.

Power saving rate and return on investment analysis

The main motor power of the 502 belt conveyor in the new stripping system of xiaolong dam is 2x800kW, and the ac contactor is used for speed switching. Due to the large power, the impulse current is large when starting the gear shift, and the medium-high speed operation is not stable. A large amount of electric energy is consumed in the rotor resistance, resulting in a huge waste of energy. At the same time, the operating environment of workers is also extremely harsh, in need of transformation.

Because the frequency converter has the advantages of soft start, smooth speed adjustment in a large range, and significant energy saving effect, etc., so after many investigations, I decided to adopt the amb-hvi high voltage series frequency converter produced by shenzhen ambition electronics co., ltd. to transform the system with frequency conversion. After several months of operation, it was proved that the effect of the transformation is quite ideal.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|