Atmospheric hot water boiler heating system has been greatly developed in China because it has eliminated the possibility of explosion and brought many outstanding advantages. In recent years. Many departments on the development of atmospheric pressure hot water boiler heating system for a lot of work, usually focus on the opening and closing valve, such as controlled by the hydraulic control to the electromagnetic, Fu ball control, spring control to reduce the floating ball size l, and will generally floating ball kai, closing valve to hydraulic floating ball valve opening and closing, etc., but the working principle of heating system there is no fundamental change. In order to ensure the safety of the heating system of atmospheric pressure hot water boiler, attention should be paid to the constant pressure problem of the heating system, the negative pressure problem of the upper pipeline and the outlet pipeline of the boiler, the problem of the inlet vaporization and temperature resistance of the circulating pump, and the problem of the boiler oxidation corrosion. In addition, according to the characteristics of the heating system, it is more and more important to debug the system correctly. The heating system of atmospheric pressure hot water boiler in China can be divided into single point constant pressure system and double point constant pressure system according to the flow direction of water in the radiator and the difficulty of exhaust.

System requirements:

1. There are three boiler control and circulation, water refilling system;

2. Each boiler has a blast and draft system, the basic requirements for constant pressure control, some requirements for constant pressure, constant temperature control;

3. Fully automatic and partial single control are required;

4. Requires partial maintenance and uninterrupted operation of part of the system;

5. There is a centralized monitoring system in the dispatch office.

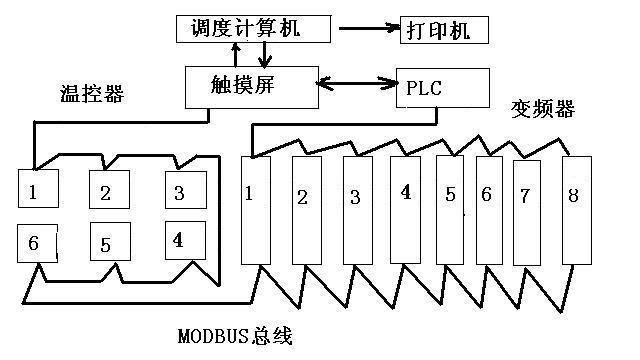

The system diagram is as follows:

The frequency converter is set by the input and output terminals connected with the external circuit. There are two states: manual and automatic. The manual state is regulated by the potentiometer to set the frequency, while the automatic state is controlled by the output signal of PLC. In practical application, the system has high automation, intuitive display, obvious power saving effect, and prolongs equipment life.

The boiler system is transformed by frequency conversion. The specific situation is as follows:

1. Frequency converter: AMB300 series frequency converter 8, power from 22KW to 200KW;

2. PLC: SPB30 PLC is selected. Due to the powerful processing function of Siemens human-machine interface, most of the functions can be realized through the touch screen;

3. Man-machine interface: Siemens man-machine interface, which can realize data processing operation. The relevant mathematical model is built in the man-machine interface to enrich processing instructions:

4. Low-voltage electrical appliances are mainly used for protection and switching, which are controlled by manual and PLC. The air switch adopts EA series, and the contactor adopts sc-e series.

5. Temperature controller USES Fuji PXR4TE series, with Mod bus communication.

This system makes full use of the powerful integration function of the man-machine interface of anbangxin inverter, and combines the inverter, PLC and thermostat with the host computer to achieve data sharing and control integration.

In the variable frequency speed control of the boiler induced fan, the frequency of the motor is automatically adjusted according to the different working conditions of the boiler by using the section speed function of the frequency converter, so as to achieve the purpose of adjusting the induced air volume. This boiler is a boiler with negative pressure combustion. If the pressure in the furnace is high, the flame may spurt out, damaging equipment or burning personnel. However, if the negative pressure in the furnace is too large, too much cold air will be inhaled, resulting in lower furnace temperature and increased heat loss. The boiler shall be started slowly and the starting process shall be:

Water system inspection

Start the induced draft fan

(3) start the boiler, at this time the boiler automatic control system first start the blower to the furnace and the wind channel for purging

(4) ignition process, the electrode produces a high pressure electric spark, fuel combustion began to ignite, burner solenoid valve opened, small fire, flame monitor began to work, such as normal combustion, delay for a minute, start the fire solenoid valve fire, after monitoring the fire normal, into the normal combustion stage

(5) according to the situation of dosage of steam boiler repeatedly switching between fire and small fire in the process of the operation of the boiler, the boiler automatic control system according to the different working conditions of large and small thermal dynamic valve automatically adjust the opening of the blower inlet damper adjustment blast volume size, and the induced draft fan is manually adjust the size of the throttle to adjust the ventilation rate, considering the actual boiler operation and investment costs, we use frequency converter speed capability of boiler induced draft fan variable frequency speed regulation reform.

In a complete set of heating system, air volume of the boiler drum on a machine often changes, is often due to volume changes, so the air volume requires constant adjustment, in the old system is by regulating valve to change the air volume, far away from the valve of the boiler, is not very convenient to adjust and adjustment shall not when, also, air volume adjustment is too large, the air with oxygen levels of waste heat, air volume adjustment is too small cinder residue carbon powder paint and waste of coal, thus improve the level of control, ensure that the air of residual carbon oxygen and coal powder, to effectively adjust the air flow and regulating mode must be convenient, sensitive and reliable.

In order to improve the control level of boiler air volume, and to achieve the effect of energy saving, using frequency conversion speed control mode to adjust the air volume is the plan. Due to the application of frequency control technology according to the change of gas consumption, at any time to adjust the speed of the draft fan, reduce noise pollution to the environment, reduce energy waste, extend the life of equipment, save maintenance costs.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|