Pumping unit is a kind of machine equipment, commonly known as the "kowtow machine", to extract oil by pressurizing the way out of the well. When the oil pumping unit is on the stroke, the elastic contraction of the oil pipe moves upward, driving the mechanical unplugging oil extractor to move upward and causing vibration when it hits the slip sleeve. At the same time, the forward single-flow valve is closed, and the variable diameter piston assembly blocks the oil. When the pumping unit is on the lower stroke, the tubing stretches down, driving the mechanical unplugging oil extractor downward and causing vibration when it hits the sliding sleeve. At the same time, the reverse single-flow valve is partially closed, and the variable diameter piston assembly still blocks the annular oil channel of the oil sleeve, resulting in a high pressure zone under the reverse single-flow valve, which in turn produces a reverse impact force on the oil flow channel in the formation.

Pumping unit is the main energy-consuming equipment in each oilfield. According to the capacity of each motor of 30KW (actually more than that, the most used in the oil field are 37KW and 45KW motors, some of which use 55KW and 75KW motors), the total installed capacity is over 3kw.

As the most energy-consuming equipment used in oilfield production, the load ratio of the motor driven by the pumping unit is generally low, resulting in energy waste. In the process of actual exploitation, the pumping unit is affected by many objective factors such as well depth, oil quality, impurities, sediment concentration, water content, etc., so it must adjust the stroke time and stroke length of operation, or even change the motor and the power of the motor. At the same time, due to the different geographical location, latitude, climate and other natural factors of the oil field, the oil pumping unit is required to adjust the corresponding speed according to the actual working conditions. In view of the technical requirements and social benefits of the above mentioned oilfield pumping units.

The basic requirements of the pumping unit for the motor control system are as follows:

☆ large-scale, stable and reliable stepless speed regulation;

☆ has a significant effect on saving electricity.

Pumping unit frequency conversion control system diagram and control characteristics:

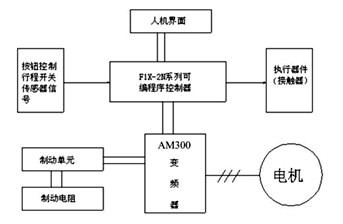

The system consists of man-machine interface, PLC, AMB300 series inverter, brake unit, brake resistance. In the whole system, PLC and frequency converter, touch screen through rs-485 serial communication.

Control system diagram:

Advantages of pumping unit frequency conversion control system after modification:

1) it can realize a variety of control over the pumping unit: air pumping control, timing start and stop control, load over-limit stop control, continuous injection and pumping control, and remote control of start and stop.

2) automatically record the pumping unit's working process and save the working status information. Automatically judge whether the pumping unit is working normally and give the alarm information.

3) AM300 series inverter has the automatic energy saving control function, which can automatically adjust the voltage according to the load, so that the motor can run in high efficiency.

4) the inverter provides multiple signal input modes, including temperature detection signal, analog signal, digital signal input and fault relay alarm output.

5) through the man-machine interface, the monitoring functions of the inverter can be realized: frequency setting, frequency rewriting, output voltage, current, etc. Control functions of inverter: operation, shutdown, fault reset, etc.

6) high efficiency, energy saving and production increase. The control program of the frequency converter is based on the actual situation of the oil field, and it can judge the running up and down stroke of the pumping unit by itself. According to the actual situation of the oil well, the speed of the up and down stroke can be adjusted in real time, so as to achieve the actual pumping, the pumping times per minute will not be changed, but the pumping amount of each pumping will be increased to improve the output of the pumping unit.

The modification scheme is developed and produced according to the basic requirements of oil field pumping unit for motor control system, which makes up for the defects of the pumping unit speed regulation scheme widely used at present, and realizes:

Wide range of continuous speed control, and maintain constant torque between zero and rated speed and short load capacity of three times rated torque;

Good power saving effect, especially for the rich oil Wells with speed regulation requirements better power saving effect.

When the reformed pumping unit is in the upstroke, the balance weight falls from the height, releasing the potential energy stored in the downstroke, helping the motor to lift the sucker rod and liquid column, reducing the energy needed by the motor in the upstroke. At present, more beam pumping units are used, and the balance balance is adopted. Therefore, in a working cycle of the pumping unit, there is an electric running state and a generator running state. When the balance balance is well adjusted, the time and energy produced by the generator are small

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|