[industry background]

An air compressor is a device for compressing gases. It is a device for converting the mechanical energy of a motor into the pressure energy of a gas. Similar to water pumps, most air compressors are reciprocating piston, rotating vane or rotating screw.

With the improvement of modern technology, customers have a higher demand for equipment parameters, operation status, alarm and other information. By timely obtaining the information of the service life and abnormal operation of the vulnerable parts, the equipment manufacturer generates the business information system, which not only provides solutions for the customer to replace the traditional manual management, improves the service level of the enterprise, but also provides the accurate information system for the enterprise after sale, so as to improve the profitability.

Air compressor is one of the main mechanical power equipment in many enterprises. Strict protection measures not only help to extend the service life of air compressor, but also ensure the safety of air compressor operators. Safety protection includes current, voltage, phase sequence, temperature, pressure protection and other functions.

[system analysis]

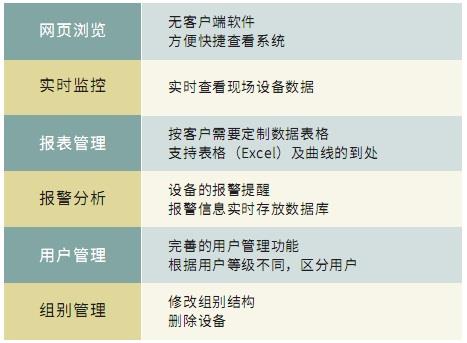

"Xinjie cloud" will be in the island state of a large number of air compressor equipment centralized management, users can be used for real-time monitoring equipment data, recording equipment information, management equipment maintenance records, to achieve the traditional manual management mode to digital management transformation. The system provides a PC WEB monitoring terminal.

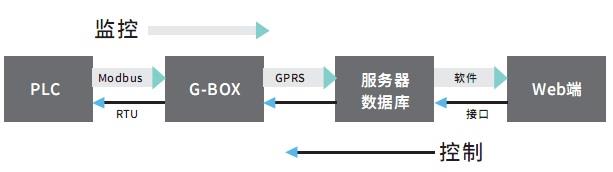

■ equipment monitoring system information flow

[system functions]

◆ real-time data includes real-time data screen, status display screen and user parameter screen. The above screen will be displayed in real time.

◆ remote control function refers to remote modification of equipment information in the WEB to control the state of the equipment. This function is only available to the administrator user in the system, which can realize remote charging, diagnosis and other occasions.

◆ the real-time data shall be stored into the database as required and presented in the form of history curve or history table through web page call.

◆ the alarm function of the device will timely capture and store the alarm status of the remote device in the database, and the user can open the alarm data interface to check. When the equipment needs to be maintained, the manufacturer can take the initiative to contact the user to solve the problem and record it in the maintenance record.

◆ maintenance records can be used as equipment ledger records. Equipment manufacturers can be used to record the equipment operation process of maintenance information, and for digital storage, traceability. End users can view the manufacturer's follow-up operation and maintenance recommendations for the security application of equipment.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|