[introduction to winding machine industry]

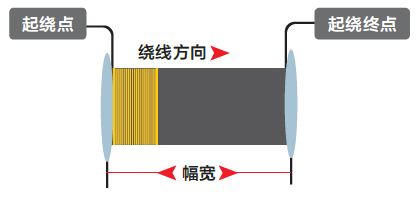

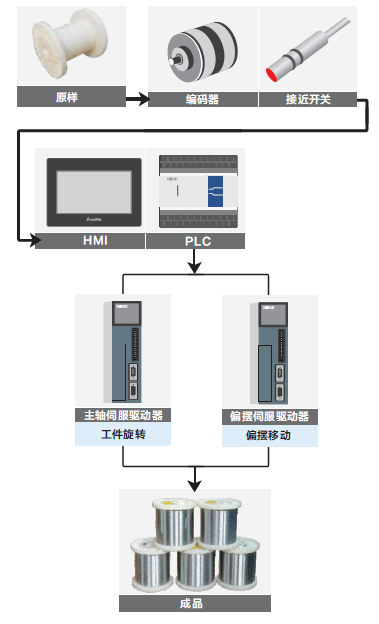

Winding machine is a high speed, precision, efficient CNC equipment, automatic winding machine is a variety of electronic and electrical equipment necessary production tools; Have a large number of high - grade CNC winding machine is also the prerequisite for enterprises to achieve automatic production. So the market for winding machine demand is very big. The diameter of the copper wire involved in this case is 0.11~0.45mm, and the stack method at the edge is adopted to solve the problem of edge winding leveling. At the same time, the tensioner is used to ensure that the copper wire has a certain toughness and the winding is neat.

Principle of winding machine

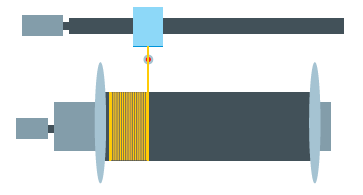

The main task of the winding machine is to rotate the spindle and the swing at the same time. At the starting point and ending point, the deflection should be reversed. Because of the lag in the direction reversal, the deviation Angle of the line is detected by the encoder to adjust the speed of the pendulum. By adjusting the alignment between the pendulum and the spindle, the copper line from the pendulum is always perpendicular to the spindle, so as to ensure that the winding does not stack. The scheme adopted in the edge part is stacked to ensure that the copper wire will not create gaps in the edge.

【 process diagram 】

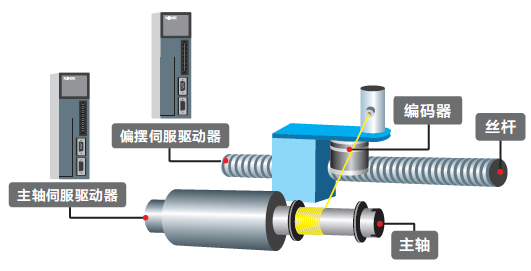

[system topology]

[program features]

◆ adopt XDM series PLC and DS3E servo driver, XDM series PLC specially for the winding machine industry to do the motion control optimization, with DS3E series servo, the system is highly responsive, speed control is more stable, efficient (at present the fastest speed is 3000rpm/min), to meet the needs of the industry for high efficiency, high precision.

◆ in the case of high speed operation, not only maintain the accuracy but also make the equipment start and stop reversing more soft, low noise.

◆ through the use of encoder feedback, winding will not stack and create gaps, winding effect is better.

◆ with the function of formula download on the touch screen, different workpiece parameters can be set, and different wire diameter specifications (0.11~0.45mm) can be conveniently and flexibly selected, so as to reduce the inconvenience of setting parameters for customers and improve production efficiency.

◆ easy to operate, all processing parameters can be modified through the touch screen system parameters, convenient and fast.

Compared with the old system of a certain brand of the customer, our PLC has made special optimization in the motion control part, and put forward a scheme to adjust the speed by feedback of the deflection servo Angle of the encoder. So our system is four times faster than the old system, and one times more accurate than the old system. (we have made a comparative test with the specification of 0.11. When the spindle is turned on at 3000rpm/min, we can ensure no stacking within 30 floors and no gaps. The old system spindle can only be turned on at 600rpm/min, and can only be wound in good condition within 15 layers. Beyond 15 layers, there will be stacks and gaps.

|

|

|

| The public, | Mobile station |

0755-81719517

0755-81719517

|

|

0755-81719530 0755-81719530 |

[email protected] [email protected] |

Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen Floor 1, 5 and 6, building 7, lijincheng science and technology industrial park, gongye dong road, longhua new district, shenzhen |

|